An output (OP) bar provides a visual representation of the current output for a piece of equipment. It can be used with multiple types of objects (control meters, variable speed drives, and control valves).

The information displayed by an OP bar may be presented as two values:

Using a furnace as an example, the output would be the temperature at which the furnace is set to operate. The actual output would be the current temperature of the furnace as it moves towards the specified setting.

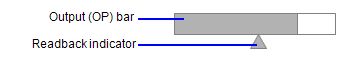

The output is represented by the main OP bar, while actual output is represented by a readback indicator.

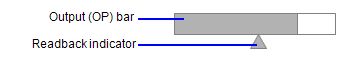

The outer rectangle represents the entire range of the output, from the low scale value to the high scale value (for example, 0—100%).

The following colors are used to represent the OP value:

Note: In the case of valves, the valve head will remain grey, but the OP bar will change to black when the OP reaches 100%.

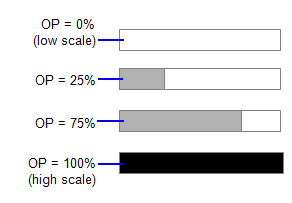

The readback indicator (also known as a feedback indicator) is a small filled triangle that is used to show:

If this information is not available from the control system, the readback indicator is not displayed.

The readback indicator displays the following colors:

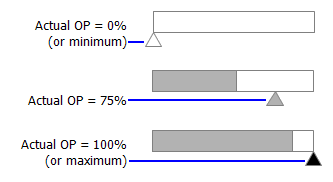

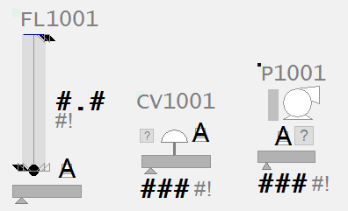

An OP bar can be specified in the Presentation Options dialog box for meters, drives and valves, but the behavior is the same in all instances. The following examples demonstrate positioning for an OP bar on a control meter, a control valve and a VSD pump.

See also

Published June 2018