Areas allow you to visualize a production facility as a set of discrete sections. You can define areas geographically (especially if parts of the plant are separated by distance or physical barriers), or logically (as discrete processes or individual tasks).

You can define up to 255 separate areas. You can then refer to these areas by number (1 to 255) or use a label to assign a meaningful name to the area (see Use a Label to Name an Area).

After you have defined your areas, you can then configure the system elements your operators will use in those areas, such as commands, objects, alarms and reports. Refer to Roles for more information on how areas and roles work together.

Note: Any system element that is not assigned to an area between 1 and 255 is automatically placed in a default area known as Area 0. Every user can view the system elements in Area 0, but without the matching privilege will be unable to control them.

Example

A simple manufacturing plant could be divided into just three areas - receipts, processing, and dispatch.

This is an effective scenario if there is a single Citect SCADA control client used to monitor each area.

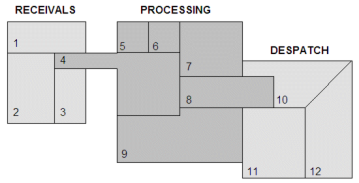

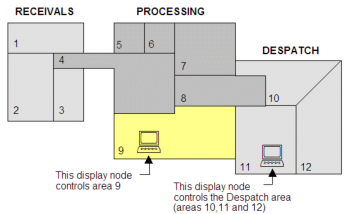

With a larger or more complex facility, you might need to define several areas, like this:

This demonstrates how you can define smaller areas that are collectively controlled by an operator or control client. This method can increase flexibility, but can introduce a higher level of complexity to your system.

You can simplify the configuration of a complex system by creating a group from multiple areas. For example, areas 10, 11 and 12 in the example above could be grouped and labeled as "Despatch" (see Create Area Groups).

You can also provide view-only access to an area (see Configure View-only Access to an Area).

See Also

Published June 2018