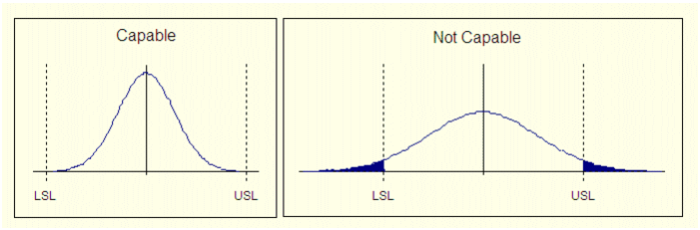

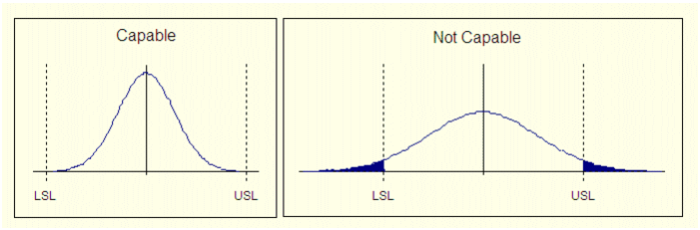

A process is said to be capable when the percentage of samples outside the specification limits is less than a predefined value. The following assumptions need to also be true:

The specification limits are a reflection of the customers requirements and are selectable. The percentage of samples that need to lie within the specification limits is calculated from the standard deviation (sigma)"3-sigmas" on either side of the mean.

Note: The "3-sigma" term refers to the boundaries which are located 3 standard deviations on either side of the center. For a normal distribution 99.74% of the samples are expected to fall within this boundary.

Ultimately capability determines whether the process is statistically able to meet the specification or not. Reducing the effects of common variation will make your process more capable, as shown here:

See Also

Published June 2018