To use SPC effectively, understand the concept of variation. When a product characteristic is measured repeatedly, each measurement is likely to differ from the last. This is because the process contains sources of variability.

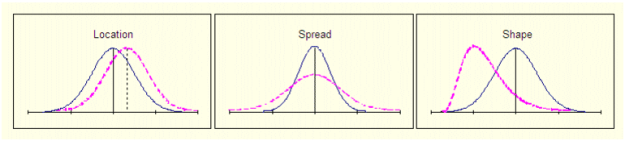

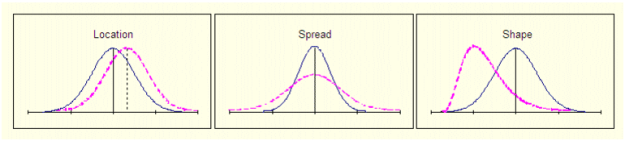

When the data is grouped into a frequency histogramA bar graph that shows frequency of occurrence versus value. Quite often the data is fitted to a distribution such as a normal distribution. ., it will tend to form a pattern. The pattern is referred to as a probability distribution and is characterized in three ways:

Variation is generally categorized into one of two types:

Statistics indicate that common variations account for about 85% of departures from process quality requirements. Usually these departures require solution at the management level.

Statistics indicate that special variations account for about 15% of departures from process quality requirements. Typically these departures require local action (equipment repair and so on) for solution.

See Also

Published June 2018